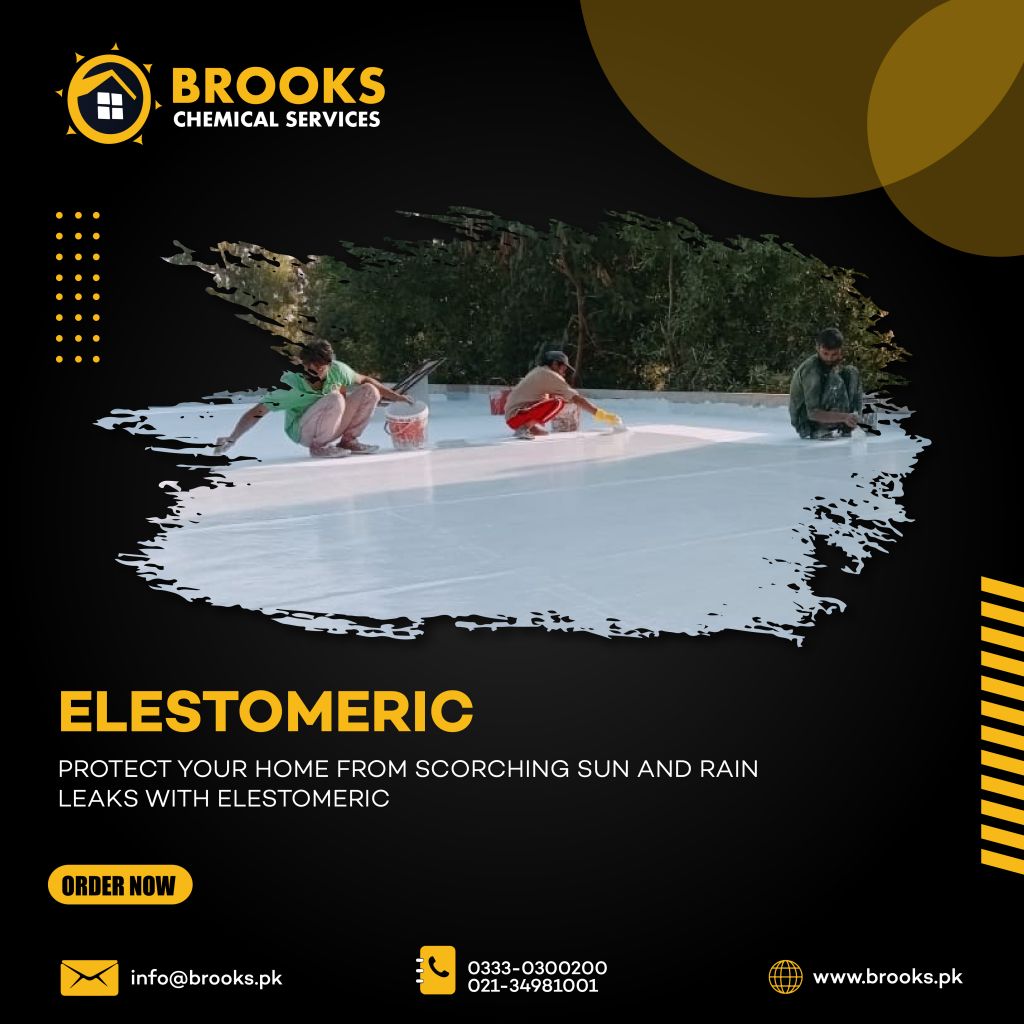

Elastomeric Coatings by Brooks Chemical Services: Waterproofing and Heat Proofing for Your Building

Elastomeric coatings are a popular and effective solution for waterproofing and heat proofing various surfaces. Made from a flexible and stretchable polymer, elastomeric coatings are ideal for protecting structures from environmental elements while offering several other key benefits.

What are Elastomeric Coatings?

Elastomeric coatings are liquid-applied and harden into a rubber-like substance that provides a durable, protective layer. These coatings are designed to expand and contract with the surfaces they cover, making them perfect for structures that undergo movement or expansion, such as roofs and walls. The elasticity of elastomeric coatings allows them to seal cracks, prevent leaks, and protect surfaces from weathering.

Benefits of Elastomeric Coatings

1. Waterproofing Protection

Elastomeric coatings are especially effective for waterproofing because they form a seamless, flexible barrier that prevents water infiltration. This makes them ideal for surfaces prone to expansion or contraction, such as:

Roofs (flat or sloped)

Walls (especially exterior surfaces)

The flexibility of elastomeric coatings allows them to stretch and move with the surface, ensuring a tight seal that won’t crack or leak over time. They are also ideal for repairing existing leaks or damage, offering a cost-effective solution for building owners looking to extend the life of their roofs or walls.

2. Heat Proofing and Energy Efficiency

In addition to their waterproofing benefits, elastomeric coatings also help with heat proofing. When applied to roofs or walls, these coatings reflect a significant amount of the sun’s heat, helping to maintain a cooler building temperature. This can result in:

Lower energy costs by reducing the need for air conditioning

A more energy-efficient building overall

Elastomeric coatings contribute to green building practices, improving sustainability and comfort within your property.

3. Environmentally Friendly

Elastomeric coatings are a safe, eco-friendly choice for building owners. They are low in VOC emissions (volatile organic compounds) and do not contain harmful chemicals, making them an environmentally responsible option. By using elastomeric coatings, you can enhance your building’s performance while contributing to a healthier environment.

4. Durability and Long-Lasting Protection

Once applied, elastomeric coatings form a long-lasting, resilient protective layer that can withstand extreme weather conditions. This includes:

Rain and snow

UV rays from the sun

Temperature fluctuations

By investing in elastomeric coatings, building owners can protect their structures from environmental wear and tear, reducing the need for frequent maintenance and repairs.

Why Choose Brooks Chemical Services for Elastomeric Coatings?

At Brooks Chemical Services, we specialize in applying high-quality elastomeric coatings for waterproofing and heat proofing applications. Our expert team ensures that your building receives optimal protection from the elements, improving energy efficiency and extending the lifespan of your property.

Advantages of Elastomeric Coatings:

Waterproofing that seals cracks and prevents leaks.

Heat reflection that lowers energy costs and enhances building comfort.

Durable, long-lasting protection against weather and wear.

Environmentally friendly with low VOC emissions and non-toxic materials.

Protect Your Building with Elastomeric Coatings

Investing in elastomeric coatings is a smart way to enhance your building’s durability while improving energy efficiency. Whether you’re looking to waterproof your roof or heat proof your walls, Brooks Chemical Services provides the reliable, high-quality solutions you need. Contact us today to learn how elastomeric coatings can help protect your building and reduce energy costs.

Elastomeric Coating for Maximum Waterproofing

Benefits: Elastomeric Coating

Flexible Protection, Guaranteed Results with our Elastomeric Waterproofing Coating solutions.

Gallery: Elastomeric Coating

Brooks Chemical Services

Wall Seepage Control

We Use Our Own Wall Seepage Control Solution Chemicals, Protect Your Home Walls From Many Kinds Of Seepages.. Wall Dampness Treatment.

Bathroom Leak Repair

Complete Treatment Of Bathroom Leakage Waterproofing Without Breakage Washroom Toilet Leaking Repair Services Without Any Damages Karachi

Warehouse Waterproofing

We Are Specialist Warehouse Waterproofing Services & Absolute Roofing Water Leakage Proofing And Protecting Heat Services In All Pakistan

Roof insulation services

Brooks Chemical Services Has Come Up A Simple Formula For You To Protect Your Home From The Heat Of The Sun. Best Roof Heat Protection Material

FAQs: Elastomeric Coating

What is elastomeric coating, and what is its purpose?

Elastomeric coating is a flexible, rubber-like protective layer made from acrylic, polyurethane, or silicone. Its primary purpose is to waterproof surfaces by expanding and contracting with temperature changes, sealing cracks, and preventing water intrusion. It’s specifically designed for roofs, walls, and concrete structures.

Is elastomeric coating waterproof, and can it stop leaks?

Yes, elastomeric coatings are inherently waterproof. They form a seamless, elastic barrier that bridges hairline cracks (up to 0.5mm) and stops leaks by blocking water penetration.

What are the uses of elastomeric coatings?

Common uses include:

- Waterproofing roofs, balconies, and foundations.

- Protecting concrete, masonry, and metal surfaces.

- Sealing expansion joints and cracks in walls.

- Coating swimming pools and water tanks.

How does elastomeric compare to epoxy, polyurethane, and silicone coatings?

- Epoxy: Rigid and chemical-resistant but lacks flexibility.

- Polyurethane: Flexible and durable but less UV-resistant.

- Silicone: Excellent UV resistance but less adhesive.

- Elastomeric: Superior elasticity, UV resistance, and crack-bridging ability, ideal for exterior surfaces.

How long does elastomeric coating last?

Properly applied elastomeric coatings last 10–20 years, depending on climate, surface preparation, and maintenance. Thicker coatings and UV-resistant formulas extend longevity.